Regular maintenance is essential for your infrared heaters to operate efficiently and last longer. Keeping up with maintenance tasks like cleaning heating elements and checking for damage guarantees maximum performance and reduces the risk of costly repairs. Accumulated dust and debris can hinder heat transfer, affecting the heater's efficiency. By inspecting heating elements for damage early on, you can prevent uneven heating and maintain warmth output. Remember to also clean reflectors and filters regularly to uphold efficient operation. Addressing any irregularities promptly and scheduling professional inspections annually will help you achieve peak performance and safety for your heaters.

Importance of Regular Maintenance

Regular maintenance of your infrared heaters is vital to confirm ideal performance and longevity. By conducting regular upkeep, you guarantee that your heaters maintain optimal energy efficiency levels, which not only saves you money on energy costs but also reduces their environmental impact. Proper maintenance also plays an essential role in extending the lifespan of your infrared heaters, ultimately saving you from the hassle and expense of premature replacements.

Maintaining your infrared heaters involves tasks such as cleaning the heating elements, checking for any signs of wear or damage, and verifying that all components are functioning correctly.

These routine checks not only enhance the energy efficiency of your heaters but also contribute to extending their overall lifespan. Neglecting maintenance can lead to decreased performance, higher energy consumption, and potentially costly repairs.

Taking the time to perform regular maintenance tasks will pay off in the long run by keeping your infrared heaters operating at their best and maximizing their longevity.

Checking for Dust and Debris

Inspect the infrared heaters for accumulated dust and debris to confirm ideal performance and efficiency. Dust accumulation on the heating elements can hinder the transfer of infrared heat, reducing the effectiveness of the heaters. Regularly checking for dust and debris is essential to make certain that the heaters operate at their best.

To remove dust and debris, start by unplugging the heaters and allowing them to cool down completely. Use a soft brush or vacuum cleaner with a brush attachment to gently clean the surface of the heaters.

Pay close attention to vents and grilles where dust tends to accumulate. For stubborn debris, a damp cloth can be used, but verify the heaters are completely dry before plugging them back in.

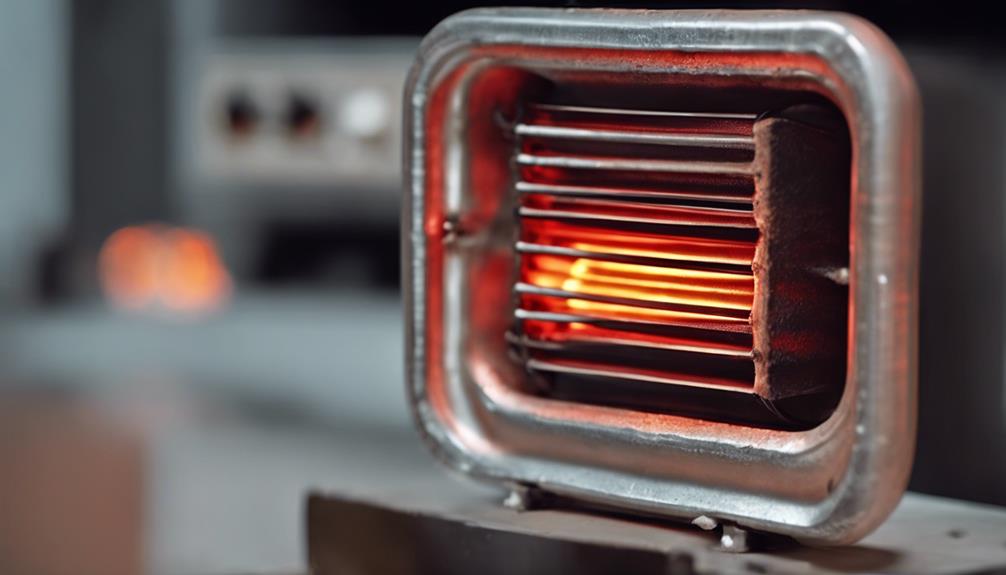

Inspecting Heating Elements

Using a flashlight, carefully examine the heating elements for any signs of damage or discoloration. The heating elements are vital components of an infrared heater, responsible for emitting the heat that warms your space.

Over time, these elements can degrade, impacting the efficiency of your heater. Regular inspections can help identify issues early on, extending the heating element lifespan and ensuring peak performance.

Inspecting the heating elements is essential for maintaining the efficiency of your infrared heater. Damaged or discolored elements can lead to uneven heating or reduced warmth output.

If you notice any abnormalities during your inspection, it's recommended to replace the affected heating elements promptly. By addressing these issues proactively, you can prevent further damage to the heater and maintain its effectiveness in heating your space efficiently.

Cleaning Reflectors and Filters

To guarantee your infrared heater operates efficiently, you must regularly clean the reflectors and replace the filters.

Start by turning off the heater and allowing it to cool down completely before beginning maintenance.

Remove the reflector by carefully unscrewing it from the unit. Use a soft cloth or brush to gently wipe away any dust or debris that has accumulated on the reflector. Be cautious not to damage the delicate surface of the reflector.

For filter replacement, consult your manufacturer's guidelines to determine the type of filter your heater uses and how often it should be changed. Typically, filters should be replaced every 6 to 12 months depending on usage. A clean filter guarantees that the heater functions at its best by allowing proper airflow.

Testing Thermostat Functionality

To guarantee peak performance of your infrared heater, test the functionality of the thermostat periodically. The thermostat is essential for maintaining temperature stability and ensuring efficient operation of your heater.

Begin by checking the calibration of the thermostat. Use a separate thermometer to compare the temperature readings with the set temperature on the thermostat. If there's a significant variance, the thermostat may require calibration to accurately regulate the heat output.

Next, observe the heater during operation to see if it cycles on and off appropriately based on the temperature setting. An erratic cycling pattern could indicate a malfunctioning thermostat.

Additionally, listen for any unusual noises or smells that could suggest an issue with the thermostat.

Addressing Any Issues Promptly

When noticing any irregularities in the thermostat functionality during testing, promptly address these issues to prevent potential heater malfunctions. Ignoring these problems can lead to inefficiencies in heat distribution and reduced energy efficiency.

Infrared heaters rely on precise thermostat settings to regulate temperature accurately. If you experience inconsistent heating or notice that the heater isn't reaching the desired temperature as quickly as it should, there may be underlying issues that need attention.

By addressing these problems promptly, you can guarantee that your infrared heater operates efficiently, providing ideal heat distribution throughout the space it serves. Failure to address thermostat issues promptly can result in the heater working harder than necessary, leading to increased energy consumption and potentially higher utility bills.

Regularly monitoring and maintaining your infrared heater's thermostat functionality is vital for its overall performance and longevity. By promptly addressing any irregularities, you can maximize energy efficiency and guarantee consistent heat distribution in your environment.

Scheduling Professional Inspections

Consider scheduling annual professional inspections for your infrared heater to confirm peak performance and safety.

Maintaining a consistent maintenance frequency is essential in making certain that your infrared heater operates efficiently and remains safe for use.

Professional services offer a thorough assessment of your heater's components, identifying any potential issues before they escalate.

During these inspections, technicians can check for gas leaks, verify proper ventilation, clean heating elements, and confirm all connections are secure.

Conclusion

In summary, regular maintenance is essential for the proper functioning of infrared heaters.

By checking for dust and debris, inspecting heating elements, cleaning reflectors and filters, testing thermostat functionality, and addressing any issues promptly, you can guarantee that your infrared heater continues to operate efficiently.

Don't forget to schedule professional inspections to catch any potential problems before they escalate.

Stay proactive in maintaining your infrared heater for peak performance and longevity.